Affine

TOOL GRIP CUSTOMIZATION FOR THE PREVENTION OF WRIST INJURIES

Capstone project 2020-2021

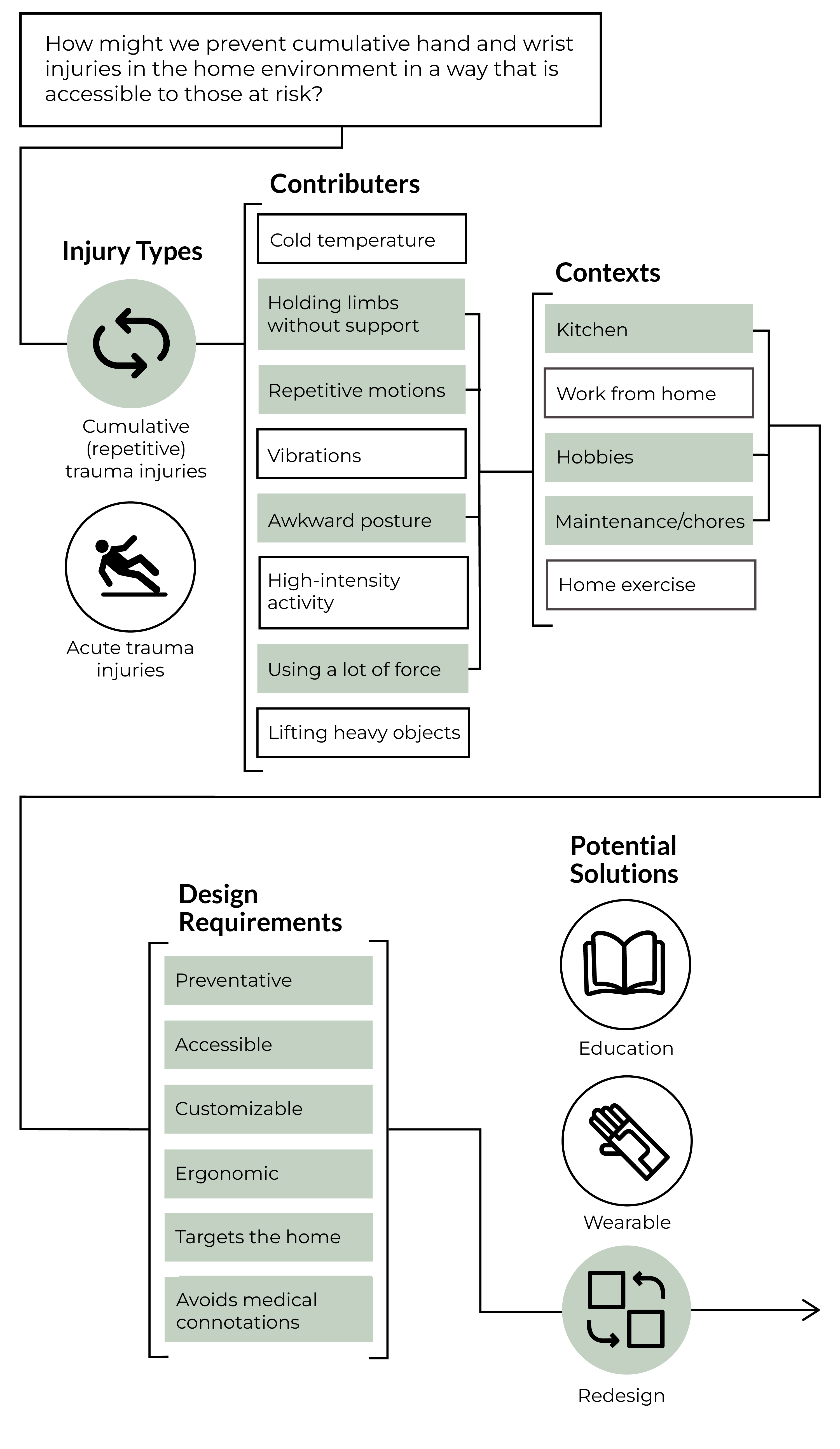

BRIEF:

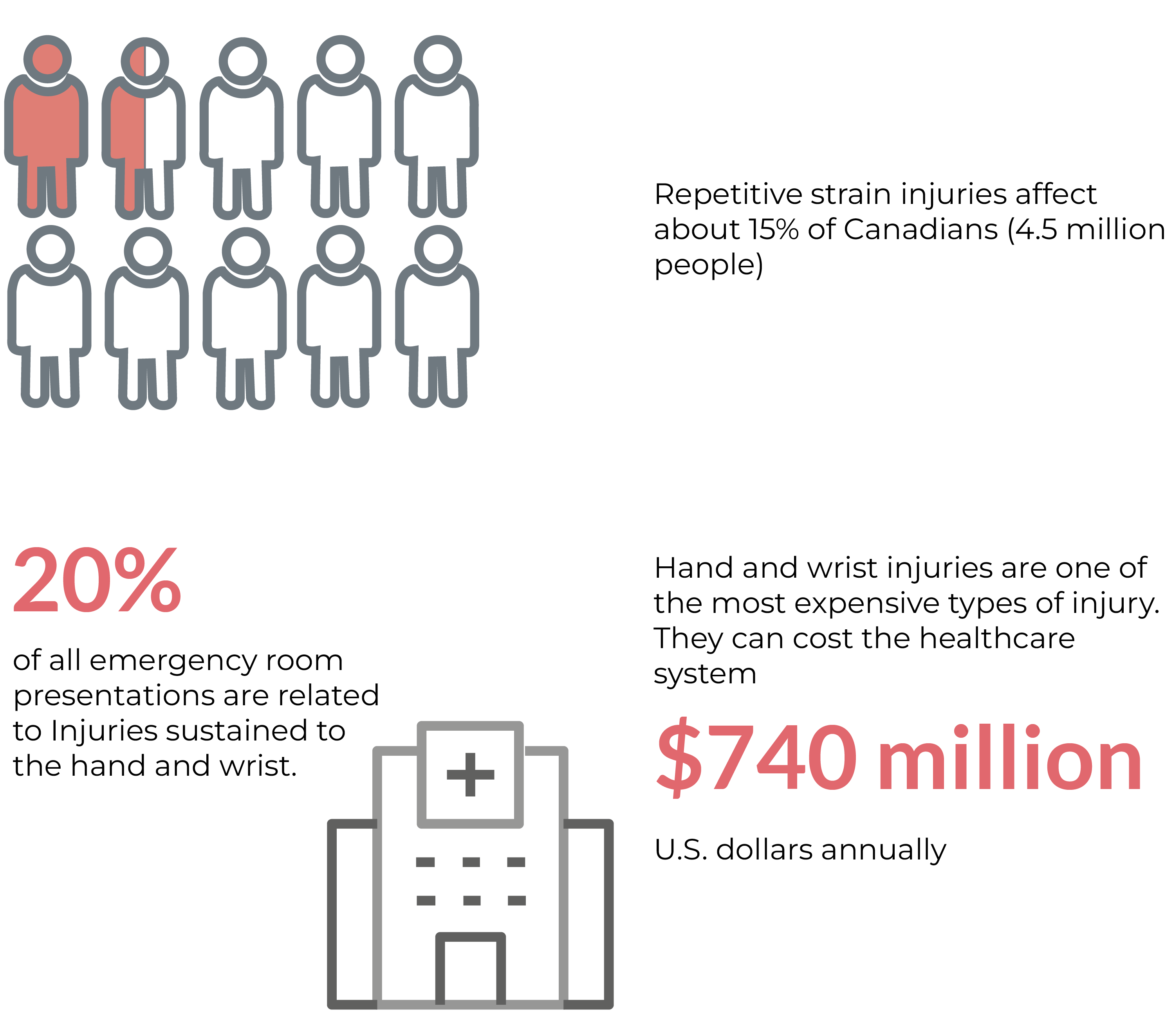

Wrist strains and sprains are one of the most common types of injuries. They can be caused by a variety of factors, including overexertion, repetitive motion, motor vehicle incidents, sports, and slips, trips, and falls. Little is currently done to prevent these types of injuries in the home environment where 34% of wrist injuries occur. This project consisted of 3 months of intensive research and 3 months of design.

Role:

Project managment, research, design and development

Background

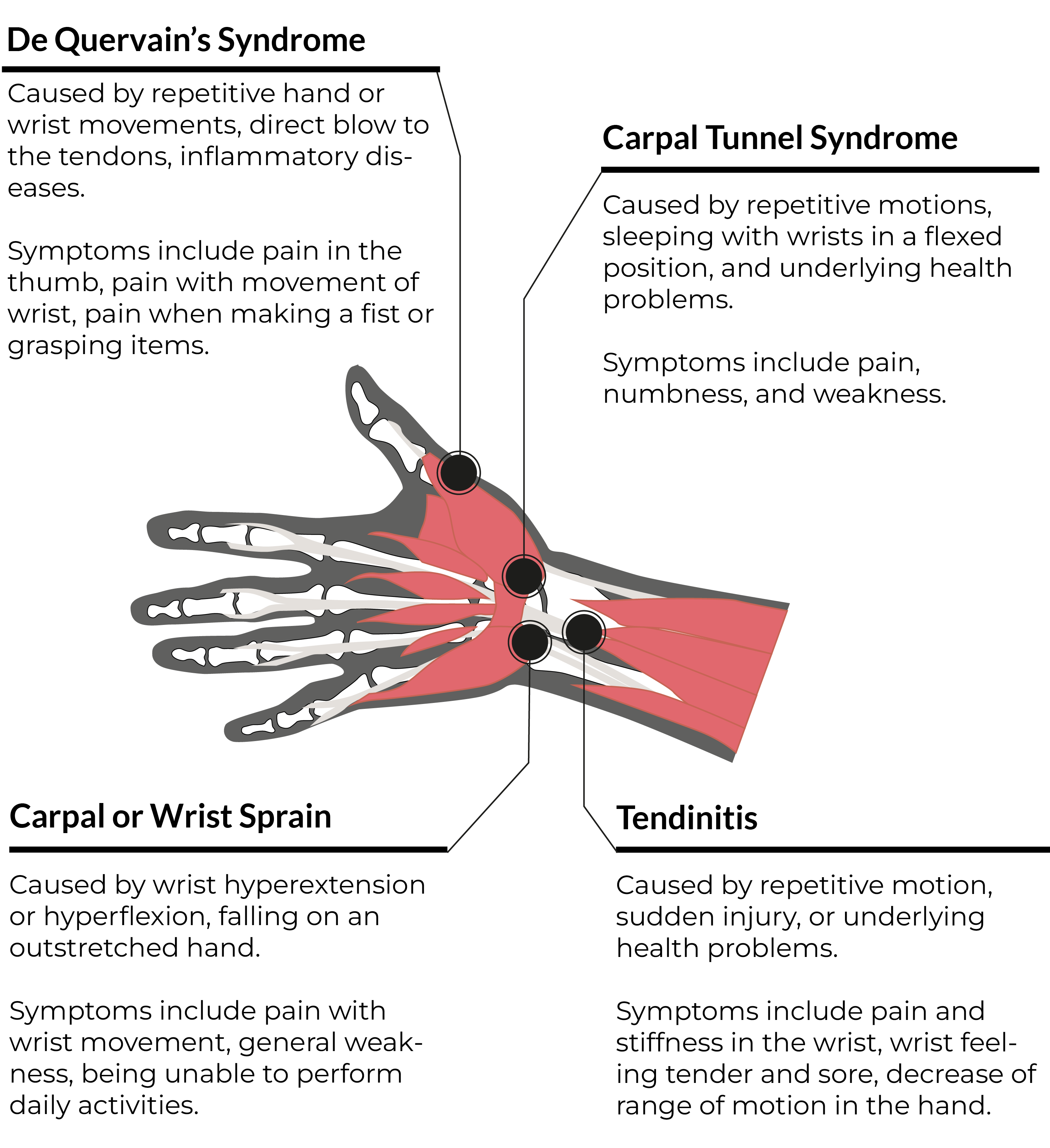

Cumulative injuries (also called repetitive strain injuries) often don’t have a single, distinct cause but are built up over time. These injuries have the potential to affect anyone, but those with genetic predispositions, pre-existing conditions, or who spend a particularly large amount of time doing repetitive tasks in an awkward position are more likely to be affected.

Process

This project consisted of a three month research period followed by a three month design period. This process began with a literature review and a number of expert interviews. I spoke to people from variety of fields including hand surgery, hand therapy, and wrist brace design. All of these interviews provided important insights that impacted the rest of the design process. I also surveyed and spoke directly to people currently experiencing hand and wrist pain to gain a better understanding of what particular issues are currently being overlooked.

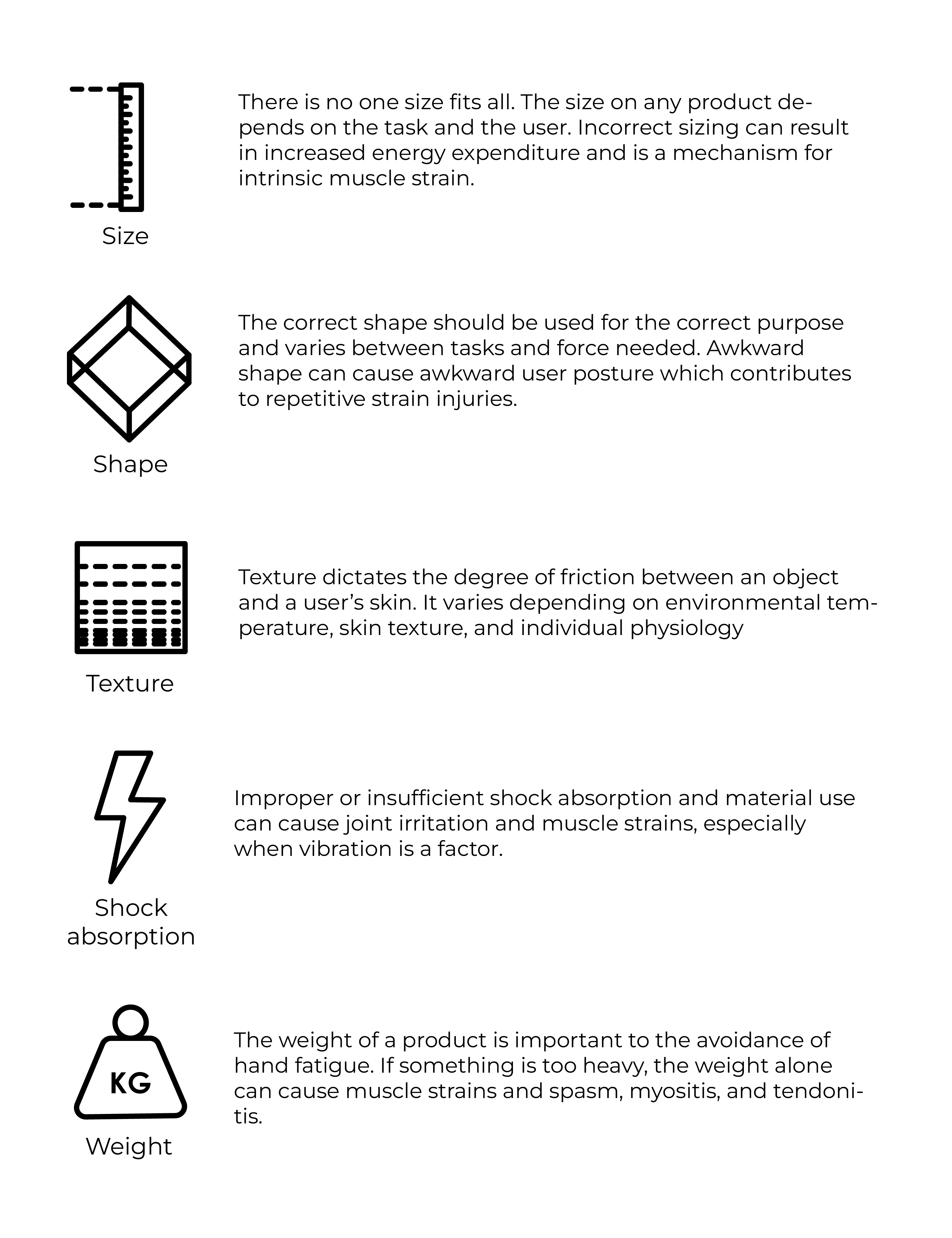

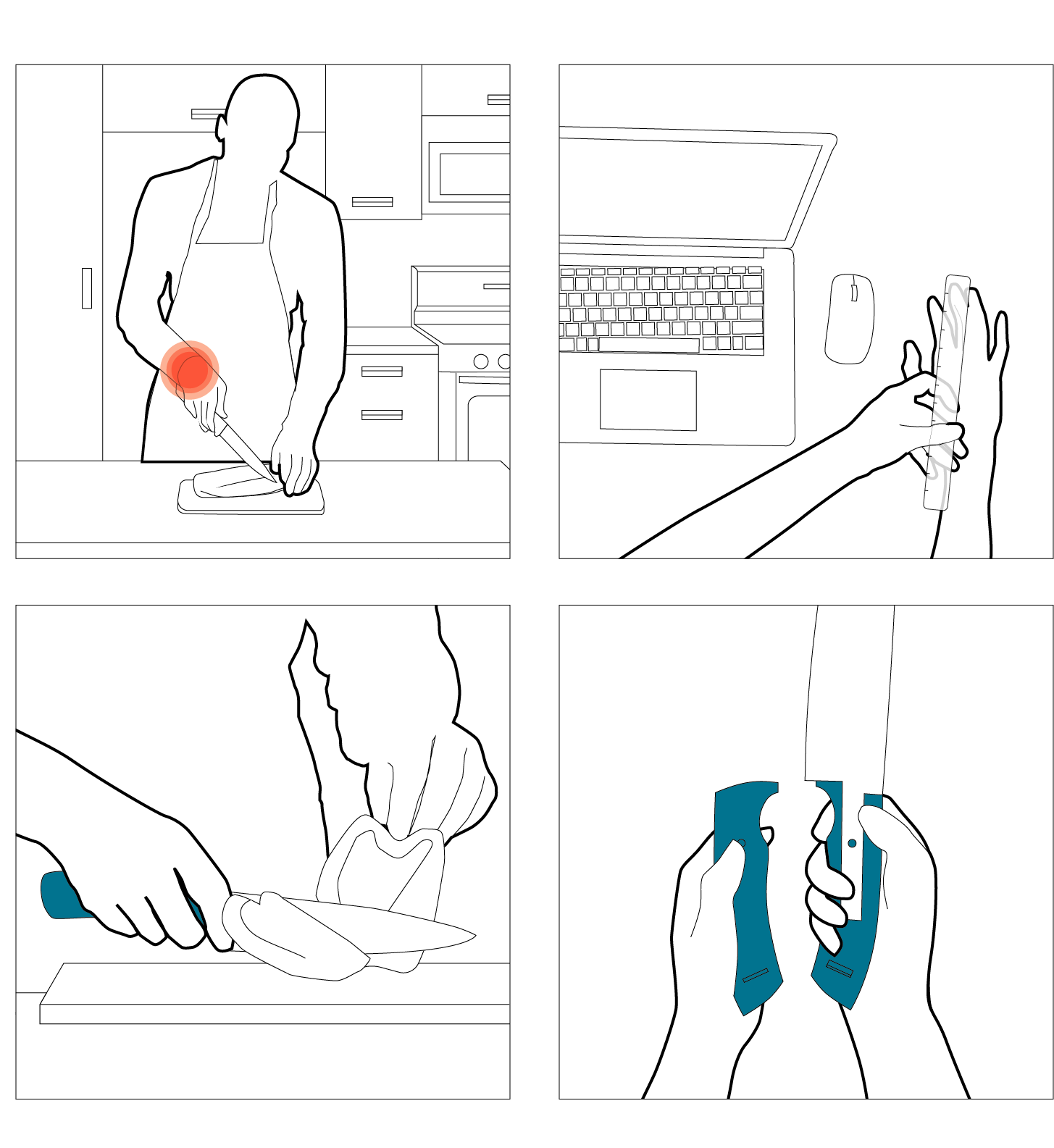

The health issues caused by using the wrong shaped or sized tools for the wrong tasks became apparent in my research and also reflected by my personal experience with wrist pain. The more I thought about it, the stranger it seemed that the tools we use at home might not fit us. Other product like clothes to desk chairs are adjustable, customizable, or sized, so why not the tools we use everyday?

Key design considerations

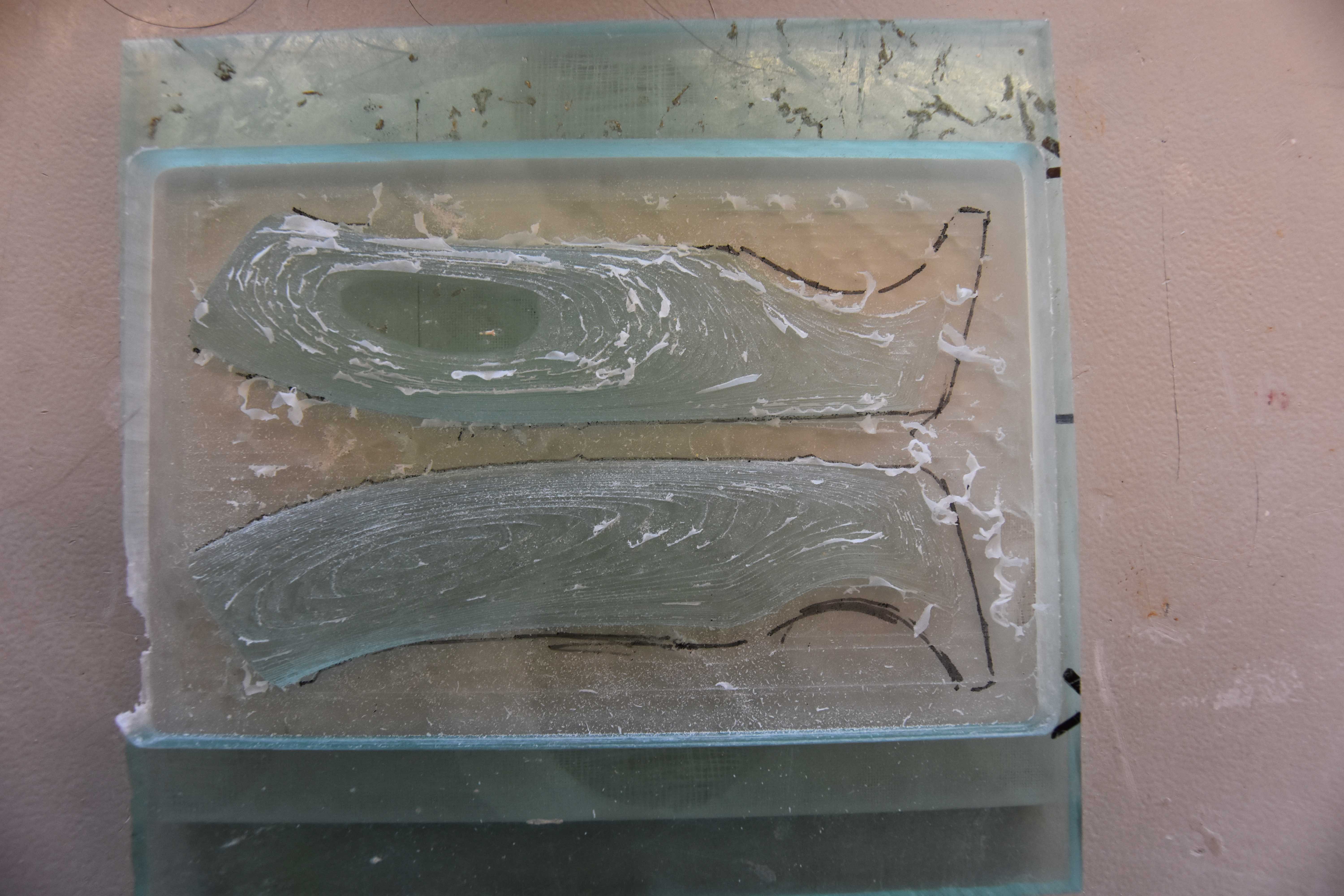

Visual language

I was inspired by smooth, swooping, and asymmetrical lines guided by the form of the hand and mixed colours and materials with transparency, layered to give a radiating tree ring-like pattern.

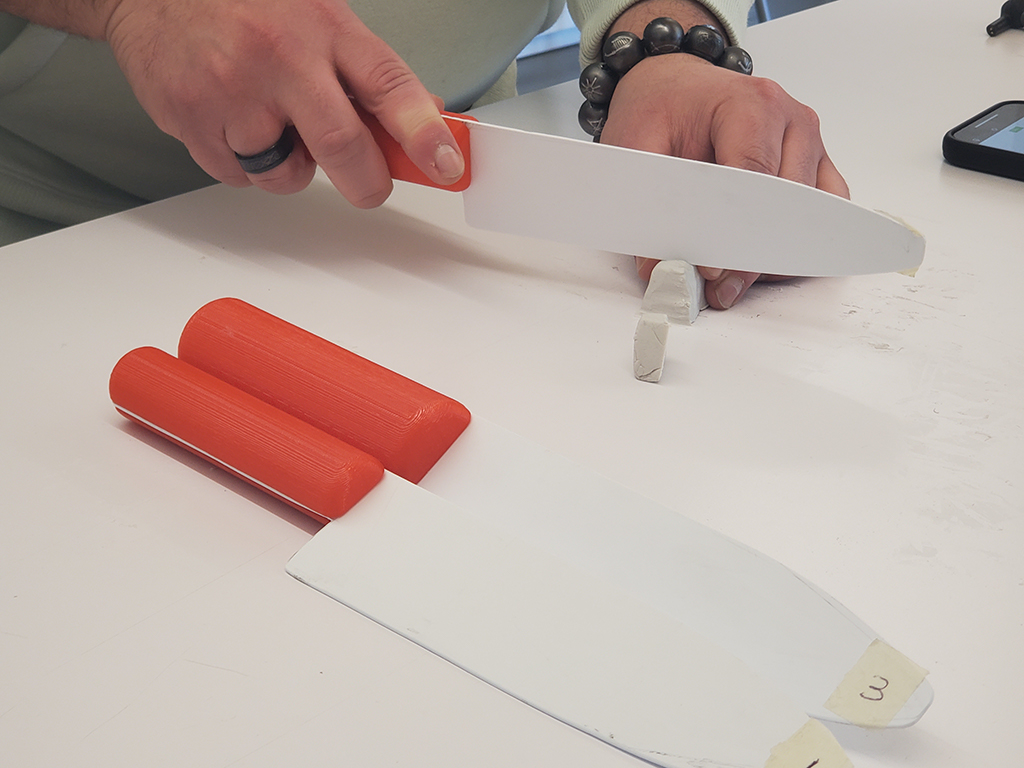

Prototyping

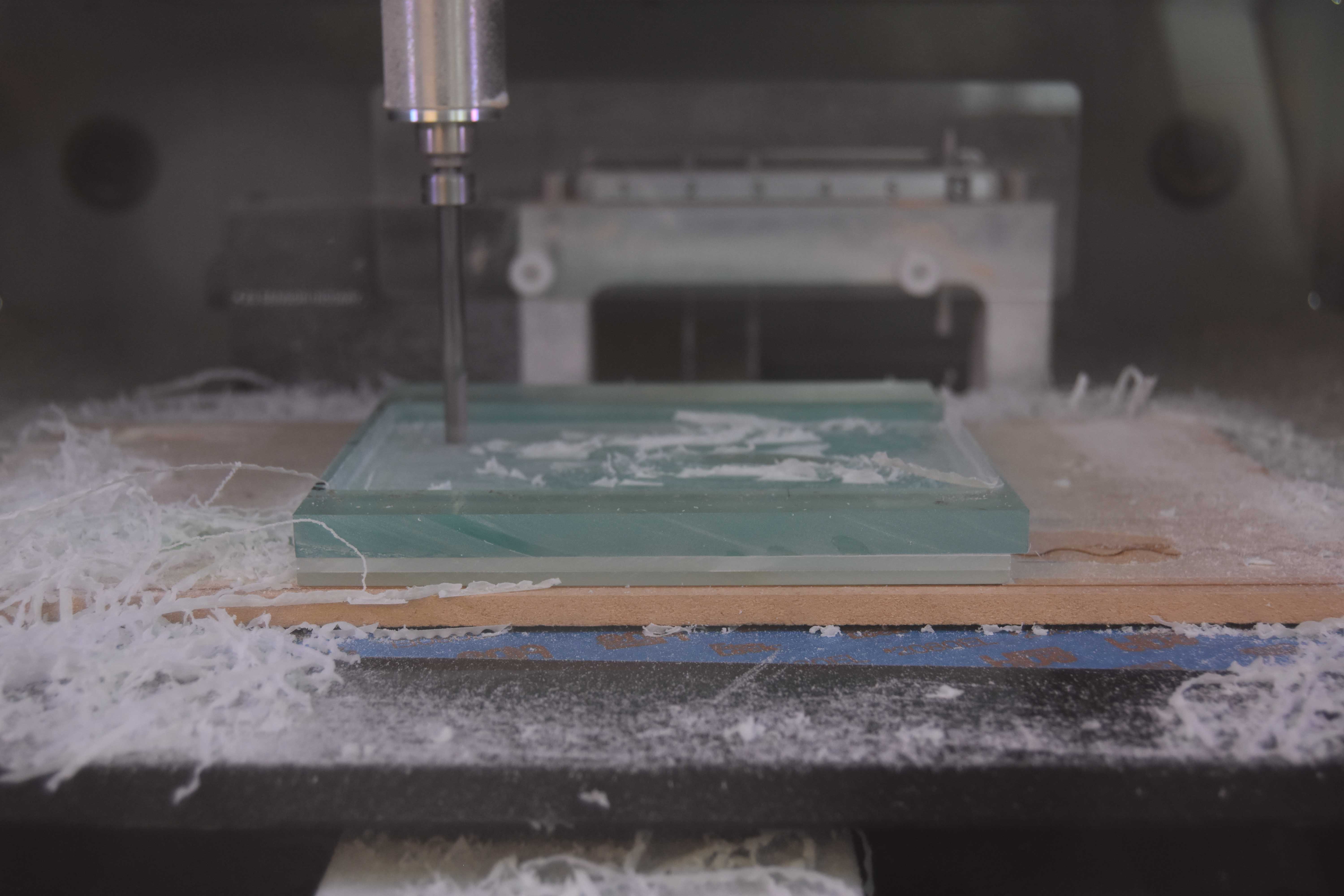

Prototyping was a constant, ongoing process throughout this project. I began with lots of quick prototypes with plasticine, experimenting with ways of supporting the curves of the hand. From these quick plasticine experiments I moved on to foam modelling. As I continued prototyping throughout the concept development, my models became more defined and I moved onto 3D modelling, and finally 3D printing and CNC.

Material and Manufacturing Exploration

With a form in mind I began to experiment with a few materials. I started by cutting and laminating materials I had on hand and creating an approximation of the form. I wanted to create a unique, layered look without creating a monstrous hybrid of materials. Through this early process I was able to determine the best layer sizes for desired outcome and get a feel for the weight and workability of different materials. At the same time I began to look further into construction options. A key consideration in anything I design is disassembly and repairability. With this concept in particular, I wanted to prolong the product’s lifetime by letting users replace or swap out handles when necessary.

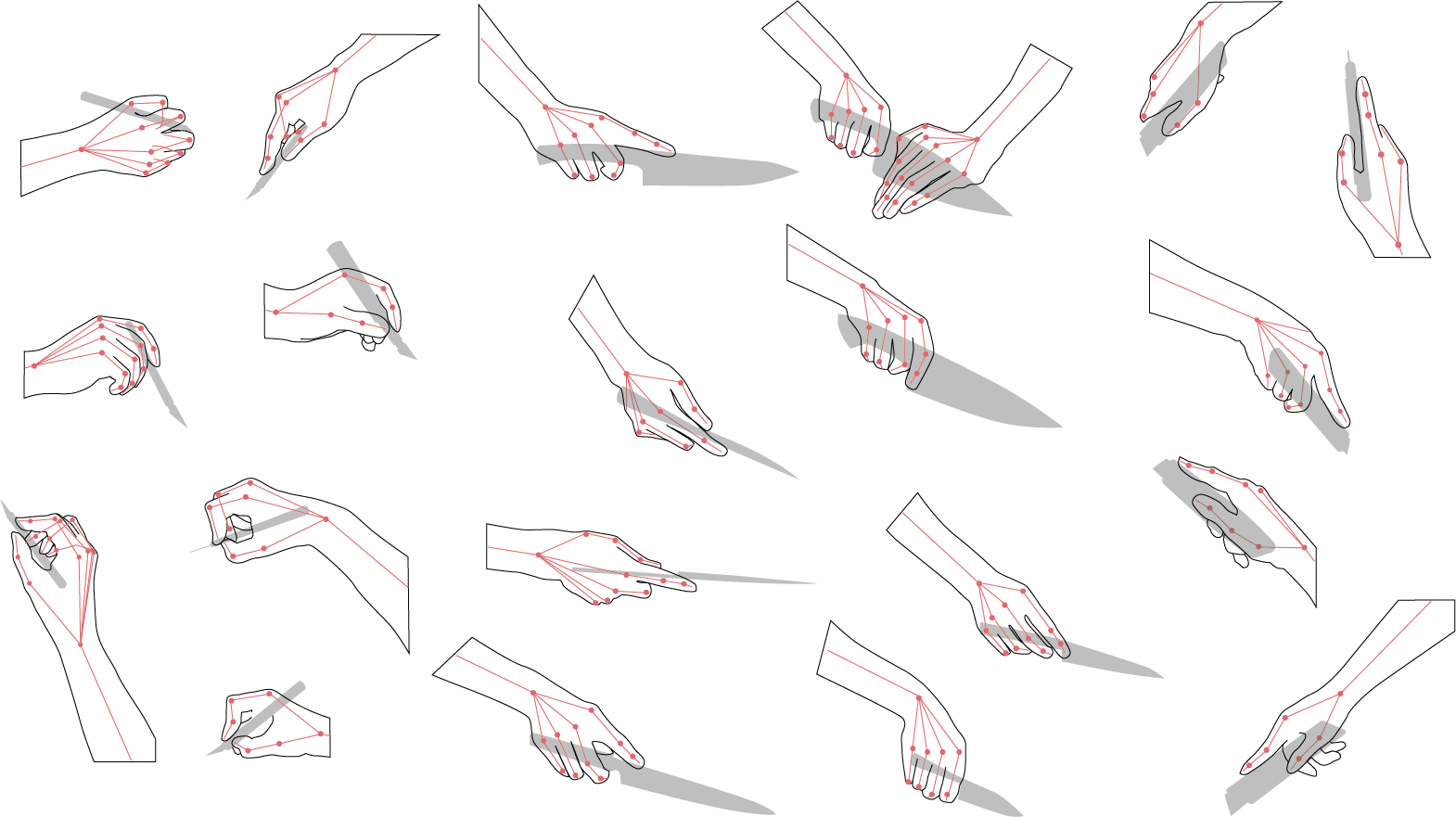

Testing and Ergonomics

The goal was to achieve a form that was very comfortable and fit in the hand well, while also not making a form so unusual that it became unrecognizable as a handle. Aesthetically, the form needed to be balanced and fit an “ergonomic look”, while functionally, it needed to be manufacturable by CNC and have clear points of manipulation within the 3D model/sketch to allow for customization. I made many models, experimenting with both form and function. I then charted them by some key metrics, including my initial design criteria, to determine what form to move forwards with. By the very definition of my concept, the form is not stagnant, it is variable, so whatever form I chose was only just the starting point.

Final Design

Affine is a system for tool grip customization for the prevention of wrist injuries. It consists of a physical design in the form of a set of exchangeable knife handles. There are future opportunities to utilize unique and innovative materials and technology for production. Things like 3D printed wood or metal could lower waste while increasing longevity. I believe the concept behind my design could be applied to many other products and sectors. I particularly see opportunity in the trades sector where current sizing caters to male dimensions and safety is of much higher priority then it is in the home.